FILTERPRESSES

Filter presses are batch wise operating pressure filters for the solid liquid separation of suspensions. They offer several distinct advantages, such as excellent separation quality and, compared to other dewatering equipment, high filter cake solid content.

Subject to sludge volume, filtration characteristic, chemical composition and filter cake discharge behaviour, We provide an optimum machine design tailored to your individual process requirements.

All the machines are available as chamber or membrane filter press with plates sizes from 300x300 mm till 2500x2500 mm.

Our Offer:

- Chamber- and Membrane Filterpresses

- Filter plate transport: manuell oder automatic

- Automatic Filter cloth cleaning device

- Cake discharge systems

- Spare parts: filterplates, filtercloths, cylinder, etc.

- Feedingpumps and polymerunits

- Screw conveyors or conveyor belts

- Control panels

- Compressors

- Consultancy and service

Manual Filter Press

Optional accessories:

- Drip tray

- Splash protection cover

- Frame in stainless steel or stainless steel cladding

Sidebar Filter Press

Sidebar filter presses combine an economic design with the possibility of a high automation degree. Orginating from a basic design this machine type could be modular configured on the customers demand.

Optional accessories:

- Automatic filter plate transport

- Automatic Filter cloth cleaning device

- Drip trays

- Cake discharge systems

- Corrosion protection of wetted parts

- Splash guards

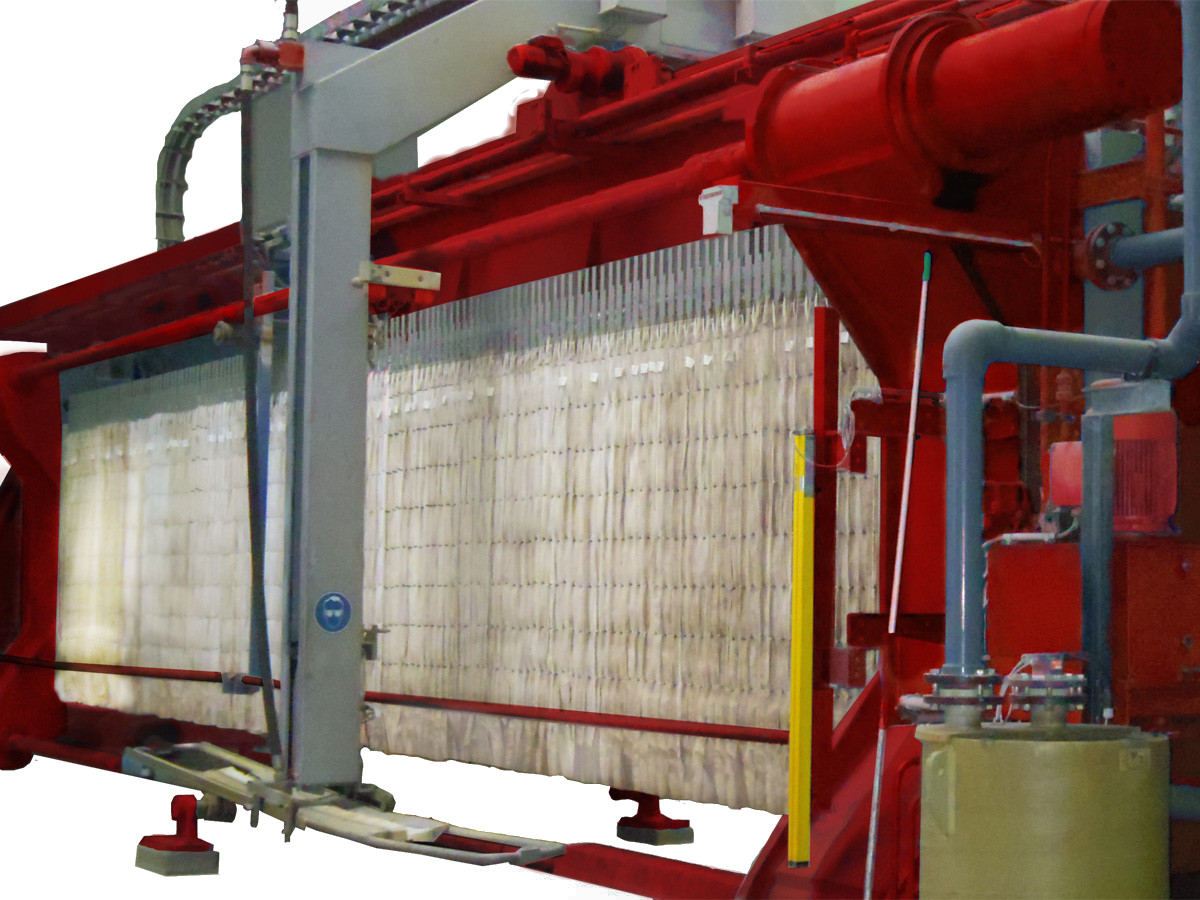

Overhead Filter Press

Optional accessories:

- Automatic filter plate transport

- Automatic Filter cloth cleaning device

- Drip trays

- Cake discharge systems

- Corrosion protection of wetted parts

- Splash guards

Tension bar Filter Press

Optional accessories:

- Automatic filter plate transport

- Automatic Filter cloth cleaning device

- Drip trays

- Cake discharge systems

- Corrosion protection of wetted parts

- Splash guards